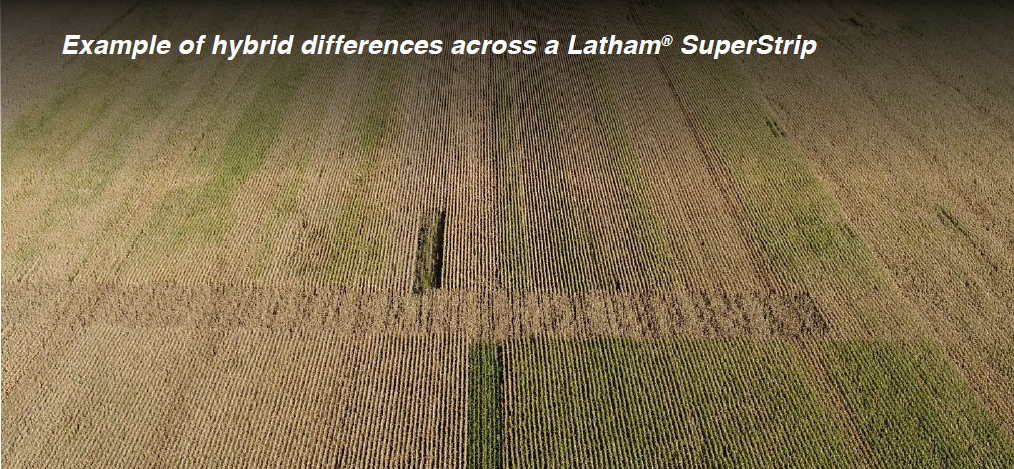

One objective of Latham’s SuperStrip plot program is to help evaluate experimental seed products. Now that the 2017 harvest data has been analyzed, it’s my pleasure to introduce three soybean lines as mid-season releases for the 2017-2018 sales year.

These new soybeans come from our research on a new herbicide trait, the HPPD inhibitors, or Herbicide Group 27 compounds. The active ingredient being targeted is isoxaflutole, which is the base chemistry in several corn herbicides like Corvus® and Balance® Flexx.

You may have seen early announcements that the “Balance™ GT” soybean trait had cleared regulatory processes. It’s important to understand that as of press time, the EPA has NOT approved any isoxaflutole compounds to be sprayed over the top of soybeans. We are releasing these three cultivars as “GT” soybeans since they are cleared to be sprayed with glyphosate products only.

Remember to check LathamSeeds.com for 2017 yield data on these newly released soybeans!

L 2187 GT

2.1 Relative Maturity

Carries the Rps1-c gene for Phytophthora, as well as Soybean Cyst Nematode (SCN) tolerance from PI 88788.vIts ratings for Sudden Death Syndrome (SDS) and White Mold ratings are excellent, and its Iron Chlorosis score is very good. This line ranked in the top three in every trial in which it was entered during both 2015 and 2016!

L 2458 GT

2.4 Relative Maturity

Produces excellent yields across Iowa and into Illinois. It carries the K-gene for Phytophthora and strong tolerance to SCN from PI 88788. The Brown Stem Rot rating is excellent. It also has very good scores for White Mold, SDS and Iron Chlorosis. It has a very attractive tawny color at harvest and is also tolerant to the STS family of herbicides.

L 2638 GT

2.6 Relative Maturity

Carries the Rps1-k gene for Phytophthora and has strong tolerance to SCN from PI 88788. It’s a fairly bushy plant type that fills wider rows easily and has shown very consistent yields across all of Latham Country in 2015 and 2016 trials. Sudden Death, Brown Stem Rot, White Mold and Iron Chlorosis ratings are all very good to excellent.