Why You Should Calibrate Yield Monitors

By: Phil Long, Agronomy Specialist

Let’s start by examining the process a yield monitor performs to capture yield information while the combine moves

through a field. The GPS receiver on top of the cab pinpoints where each piece of data is coming from; that location data goes to the monitor in your combine to integrate the location with information coming from sensors in the combine. Without correct communication between the receiver and monitor, you cannot record a yield map.

One of the two main sensors recording data is a moisture sensor, which is typically located in or on the side of the clean grain elevator or in the grain tank. The other main sensor is the mass flow sensor, which is typically located at the top of the clean grain elevator. This sensor translates the impact of the grain into an electrical impulse and uses the moisture to correlate a yield value to that sample of grain.

Systems installed on modern combines can be very accurate if properly calibrated. Calibration procedures usually require a series of loads (at least 3,000 pounds) to be run through the combine to provide the mass flow sensor with calibration standards. These calibration loads should be different amounts, and at different flow rates or combine speeds, to make sure the mass flow sensor can adjust to different yield conditions. The moisture sensor also should be calibrated; it’s important to calibrate it against an accurate tester.

There are several other important settings that should be checked before harvest starts: header height stops; flow delay settings; swath width and initial vibration settings for the mass flow sensor. Also be sure field names are in the monitor. This is not an exhaustive list, but it’s meant to serve as a reminder of what to check before harvest begins.

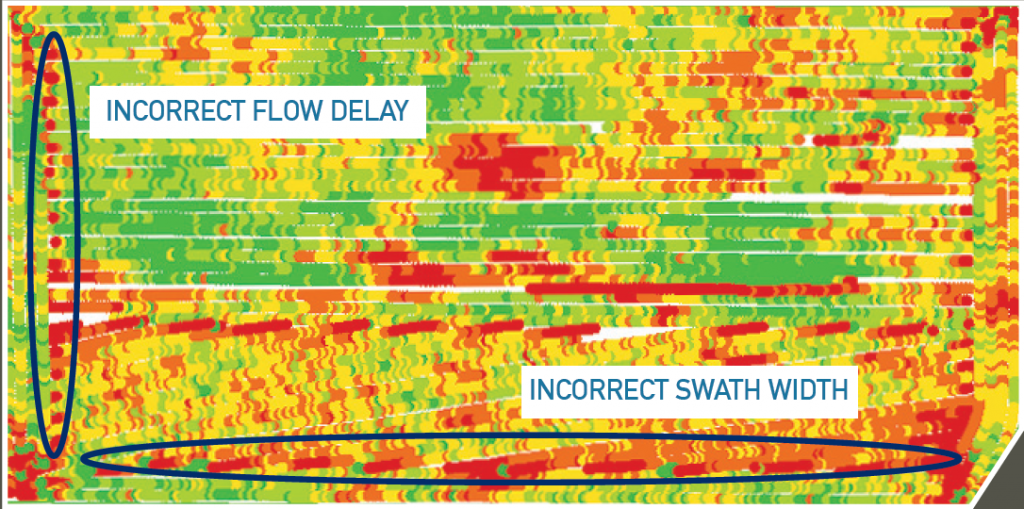

Major yield map issues that may be fixed before or during harvest are setting the correct flow delays and swath widths. If you are not harvesting with a full header because you are not using assisted steering, then bump your width down by a foot or two; that will make your yield calculation more accurate. Setting the flow delay for how long it takes the crop to begin hitting that mass flow sensor from the time your header is lowered will positively impact data quality. (See image.)

Pre-harvest is the best time to look at your yield monitor and settings. Help farmers you work with to calibrate during harvest, so they have quality data to use when making post-harvest decisions.