Optimize Silage Quality with Timely Harvest

It’s more challenging than most people think to achieve optimum harvest timing. Life on the farm would be mighty easy if the weather cooperated, machinery was always in working order, and the custom harvester came right when you called.

It’s more challenging than most people think to achieve optimum harvest timing. Life on the farm would be mighty easy if the weather cooperated, machinery was always in working order, and the custom harvester came right when you called.

Some days farming feels like you’ve been handed a bent golf club to play a mini golf course full of obstacles, water hazards, and challenges meant to distract, disrupt and impact the result. Fortunately, farmers are the golf pros of the acre. Despite all the craziness tossed at them, they face the adversity with steadfast grit and determination. Farmers keep their eyes fixed on the goal of doing their best.

Timing is everything to harvest the best quality corn silage. With corn silage harvest rapidly approaching, let’s review why timing is important.

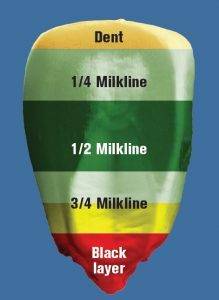

In general, 65 to 70 percent whole-plant moisture is the optimal goal range for harvest moisture. The plant is at this moisture level when the kernel is about 50 percent milk line. The starch in the kernel is like a sponge, absorbing moisture from the plant. Think about this… If you remove the entire ear, the remaining stalk contains a moisture level about 80 to 85 percent moisture. Now, add back in a normal size ear that is half milk line. The new whole-plant moisture will be between 65 and 70 percent as that added starch absorbs some of the plant moisture.

As the milk line of the kernel drops toward the tip, it adds even more starch to the kernel. Each day more starch is added to the kernel, which is absorbing more moisture from the plant. As a really broad general rule of thumb, from about one-fourth milk line stage, corn silage moisture can drop in the field around 0.5 percent each day. Moisture can drop a full percent on those hot, dry, sunny September afternoons when photosynthesis is good and starch is accumulating rapidly. Additionally, there is also some evaporation from the leaf tissues.

Once the kernel drops below half milk line, the moisture will rapidly drop below 65 percent whole-plant moisture, and it becomes more difficult to pack and ensile. Additionally, as the milk line drops, it is exponentially adding a protein called prolamin zein. This particular protein has a negative impact on starch availability and can be linked to higher fecal starch levels.

Hybrids like Latham® 5495 3122 EZR and LH 5742 RR and our leafy hybrids tend to have less of this protein. This softer, lower prolamin starch found in select dual-purpose and leafy corn silage hybrids provides flexibility in the harvest window while still giving peak harvest qualities. They can take away a little stress while you’re waiting on weather or the custom harvesting crew.

Bottom line, as harvest approaches, check moistures early and often to develop the best harvest plan to capitalize on yield and quality.